10KHZ Adaptive Inverter Dc Robot Dedicated Electric Servo Spot Welder

Details

The High frequency inverter DC welding machine is our company to develop and produce new kind of resistance welding machine. The device is the most advanced high-frequency, full-bridge soft switching inverter technology technology and DSP digital control technology, output frequency of 10,000 Hz. Transformer welding forming of small size, high output power, well, less spatter, high control precision. When welding multi-layer of galvanized steel and high strength steel,not only the solder quality, and we can do the basic emission-free. The product won four national invention patents, fifteen utility model patents and three software copyright certificate and another two international patents under patent review of the designated State.

The device has the following characteristics:

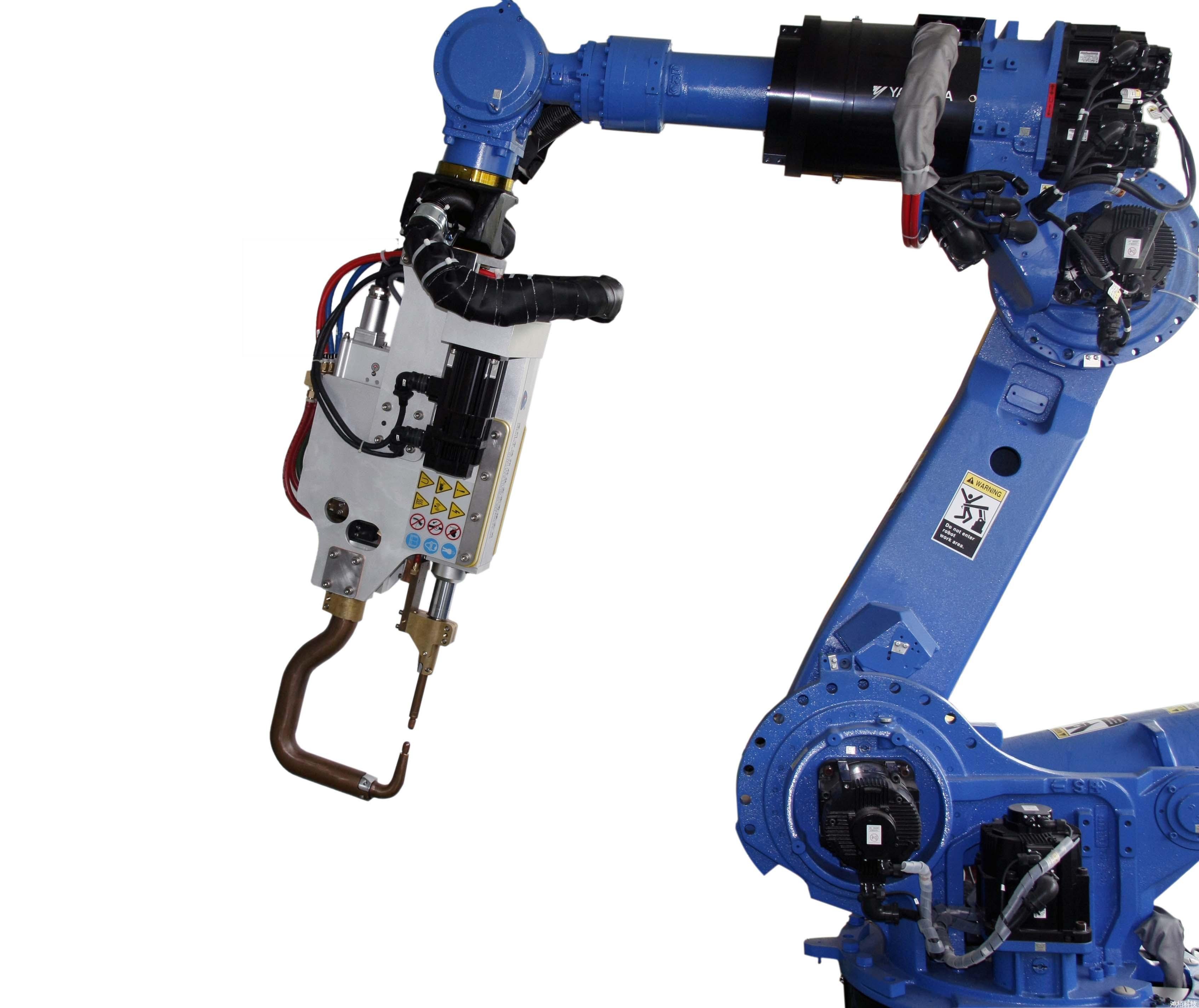

1. transformers are small, light weight, not only to achieve the integration of transformer and electrode holder, and also help reduce the overall weight of robot welding clamp.

2. hollow motor gun retract servo linear actuator can be imported, can also takethe company independent research and development and a number of patented linearactuator. The hollow motor adopts imported roller screws, its service life is 5-10 times the ordinary ball screw. Iproduced the electric cylinder structuredesign, low noise, strong rigidity, long service life, easy maintenance.

3. won a number of design patents of robot welding clamp body, procurement ofaviation aluminum processing, good rigidity and high strength, deformation issmall, to improve the weld quality, and played a positive role as a safeguard.

4. welding and robot communications hosts using the DEVICENET Protocol, also according to user requirements, configure a personalized communication module.

As national Twelve-Five major special "based on robot of car welding loaded Automation line" project of bear who one, times HF electric Servo Robot dedicated DC spot machine has was Faw sedan company of D009 models of floor line, and M3 models of main welding line, variety models used; the equipment also Yu 2013 success bid Shanghai General car D2UX platform robot spot machine project, dozens of inverse changed DC robot dedicated electric servo spot machine, specifically for the project of high strength plate welding.

C Type-Robotic Spot Welder

X Type-Robotic Spot Welder

TECHNICAL DATA

Type

Parameters

DB6-40Z

DB6-63Z

DB6-100Z

Rared input power

40KVA

63KVA

100KVA

Rated Input voltage

380V ± 10%

380V ± 10%

380V ± 10%

Safety protective current

30mA

Dielectric strength

4000V,60s(Initial---secondary)

Max.short-circuit current

12000A

15000A

18000A

welding range

0.5+0.5—2.5+2.5mm

0.5+0.5—3.5+3.5mm

0.5+0.5—3.5+3.5mm

welding rage

10-30 points / minute

10-30 points / minute

10-30 points / minute

Max.welding voltage

DC8.5V

DC8.5V

DC10.8V

weld time

5---500ms

Rated duty cycle

20%

insulation class

Class F (155 °C)

Class protection

IP54

Working temperature

5---40 ℃

Electric cylinder pressure

0---7000N

Water pressure

0.3Mpa

Cooling water flux

10L/min

12L/min

14L/min

Pedestal volume

Length 480 Width 256 Height 559

Welding clamp weight

60-90KG

65-100KG

70-120KG

Pedestal weight

30KG