Dynamic Considerations in Prediction of Fracture of Ultra High-Strength Steel During Crash

- 2018-10-16 10:56:00

- LUQIMENG Original

- 3509

High strain rate response of automotive alloys (tensile + shearcharacterization):

1、DP980 (SMDI), DP600

2、Fully quenched Usibor® 1500-AS, Ductibor® 500-AS

Effect of strain rate on fracture?

1、Shear conditions (zero triaxiality)

2、Positive triaxiality conditions

Weld failure characterization – “spot weld groups”

• Achieves shear strains easily on the order of unity with relatively constant triaxiality of zero .

• Appropriate for high rate testing in Hopkinson bar or high speed hydraulics (1-1000/s).

Issue today lies in the majority of fracture characterization for crash CAE being doneat quasi-static rates…

Potential sources of rate effects:

• Elevated strain rates

• Temperature increase through adiabatic heating (~90% of plastic work convertedto heat) *

• Inertial effects

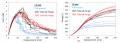

• Rate sensitivity is initially positive, but becomes negative atlarge strains

• Promotes earlier localization under shear loading

• Onset of shear cracking is determined as the point where thehardening rate is exhausted 1

• Repeatable and eliminates the need to detect fracture based on visible cracking 2

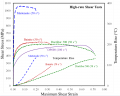

In tension, positive rate sensitivity promotes higher failure strains as strain rate increases.

In shear, thermal localizationreduces failure strain (as measuredusing DIC) with increasing strain rate.

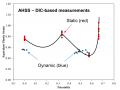

• Given the coarse meshesnecessitated in vehicle CAE, failurestrains should be measured using alength scale on the order of theelement size

• DIC virtual strain gauge length: 0.3mm) versus 3-5 mm element size

• For these materials, shear strain tofailure input to FEA decreases withstrain rate!

• Less impact on positive triaxialityregime, however, confoundingresults exist in the literature

• Earlier localization,narrower thermal fieldfor the higher strengthconditions

• Thermal localizationenhanced for higherstrength alloys

• The strong workhardening of the DP600is clearly beneficial

• Interaction between nugget, HAZ and parent metal strength(single weld)

• Test method for weld group testing (Mode I Caiman)